Yuqori darajadagi mikser

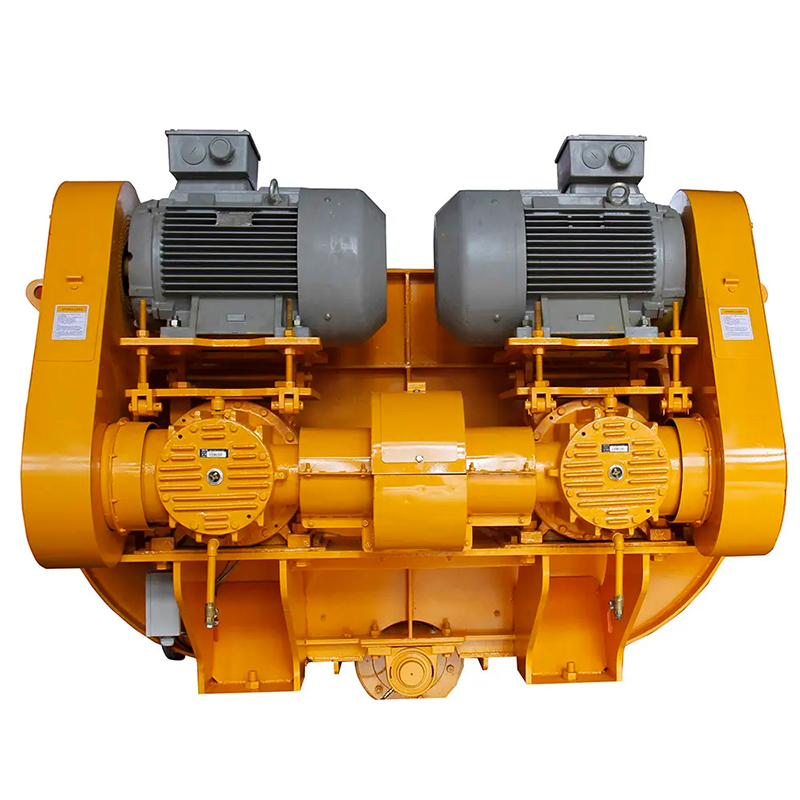

Mahsulot xususiyati:

1. Xuddi shu quvvatga ega bo'lgan boshqa mikser bilan solishtirganda 20% ni yaxshilang va 120 aralashtirish moslamasi bilan jihozlangan samaradorlikni soatiga 160 m3 ga oshirish mumkin.

2. Import qilingan vosita reduktori energiyani 15% ga tejashi mumkin va mil uchidagi havo o'tkazmaydigan muhr yiliga 20000 yuan yuan moylash to'lovini tejashi mumkin.

3. Milya uchidagi noyob pnevmatik tushirish va havo o'tkazmaydigan muhr neft ifloslanishidan qochishi mumkin.

4. JS seriyali beton aralashtirgich asosan turli navli beton ishlab chiqarish uchun ishlatiladi, u qattiq beton va past plastik beton ishlab chiqarishi mumkin. Agregat shag'al yoki shag'al bo'lishi mumkin. U asosan beton ishlab chiqarish liniyasida qo'llaniladi.

Texnik parametrlar

| Element Ti | SjJS2000-5G | SjJS3000-5G | |

| Bo'shatish hajmi (L) | 2000 | 3000 | |

| Zaryadlash hajmi (L) | 3200 | 4800 | |

| Ishlash davri (S) | ≤80 | ≤86 | |

| Maks. Agregat hajmi (mm) | Shag'al | 60 | 60 |

| Tosh | 80 | 80 | |

| Umumiy vazn (kg) | 7970 | 9565 | |

| Aralashtirish quvvati (kw) | 2X37 | 2X55 | |

Xabaringizni shu yerga yozing va bizga yuboring

![[Nusxalash] Qum ajratuvchi](https://www.zbjxmachinery.com/wp-content/uploads/1-115.jpg)