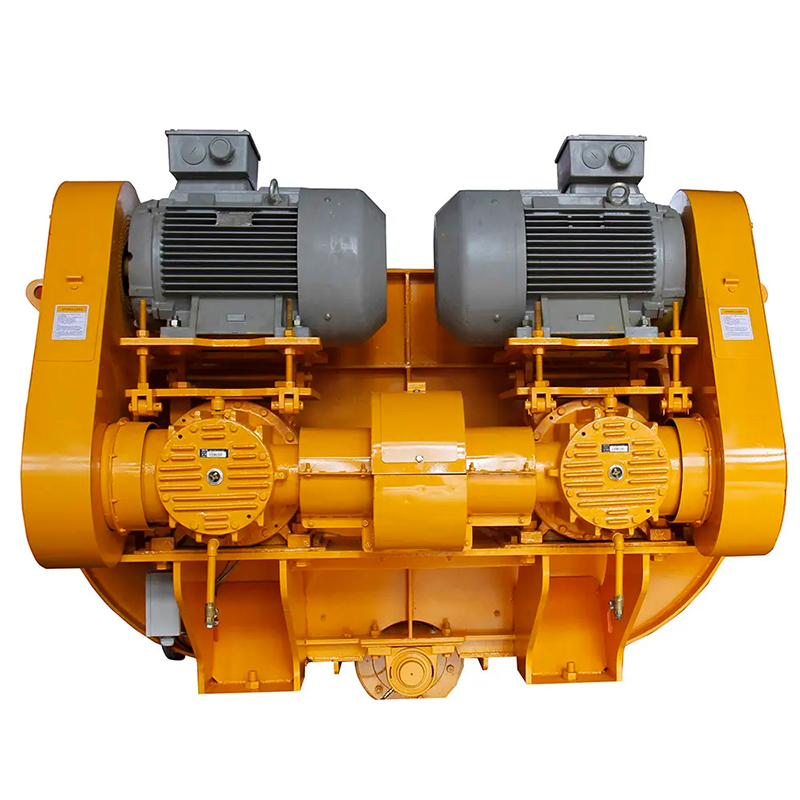

มิกเซอร์ระดับไฮเอนด์

คุณสมบัติผลิตภัณฑ์:

1. ปรับปรุง 20% เมื่อเทียบกับเครื่องผสมอื่นที่มีกำลังการผลิตเท่ากัน และสามารถเพิ่มประสิทธิภาพเป็น 160 ลบ.ม. ต่อชั่วโมงพร้อมกับโรงผสม 120 แห่ง

2. เกียร์ลดมอเตอร์ที่นำเข้าสามารถประหยัดพลังงานได้ 15% และซีลกันอากาศที่ปลายเพลาสามารถประหยัดค่าหล่อลื่นได้ 20,000 หยวนหยวนต่อปี

3. การคายประจุด้วยลมที่เป็นเอกลักษณ์และซีลกันอากาศที่ปลายเพลาสามารถหลีกเลี่ยงมลพิษจากน้ำมันได้

4. เครื่องผสมคอนกรีต JS-series ส่วนใหญ่ใช้สำหรับการผลิตคอนกรีตเกรดต่างๆ สามารถผลิตคอนกรีตแข็งและคอนกรีตพลาสติกต่ำ มวลรวมอาจเป็นกรวดหรือกรวด ส่วนใหญ่จะใช้ในสายการผลิตคอนกรีตประเภทต่างๆ

พารามิเตอร์ทางเทคนิค

| รายการ ประเภท | เอสเจเจเอส2000-5จี | เอสเจJS3000-5G | |

| ความจุจำหน่าย (L) | 2000 | 3000 | |

| ความจุการชาร์จ (L) | 3200 | 4800 | |

| ระยะเวลาการทำงาน (S) | ≤80 | ≤86 | |

| สูงสุด ขนาดรวม (มม.) | กรวด | 60 | 60 |

| กรวด | 80 | 80 | |

| น้ำหนักรวม (กก.) | 7970 | 9565 | |

| กำลังผสม (กิโลวัตต์) | 2X37 | 2X55 | |

เขียนข้อความของคุณที่นี่แล้วส่งมาให้เรา