Kuwa ku jira warshadaha dhismaha, kor u qaadida hufnaanta hawlgalku inta badan waa mawduuc muhiim ah. Mid ka mid ah hababka aan caadiga ahayn ee dareenka la helay waa qaadashada dhirta shubka ah ee aan cagaha lahayn. Laakiin maxaa dhab ahaantii ka dhigaya dhirtaas kuwo waxtar leh, maxayse dadku ogaadeen markii ay ku dhaqmayaan?

Fahamka Dhirta la taaban karo ee Cagaha La'aanta ah

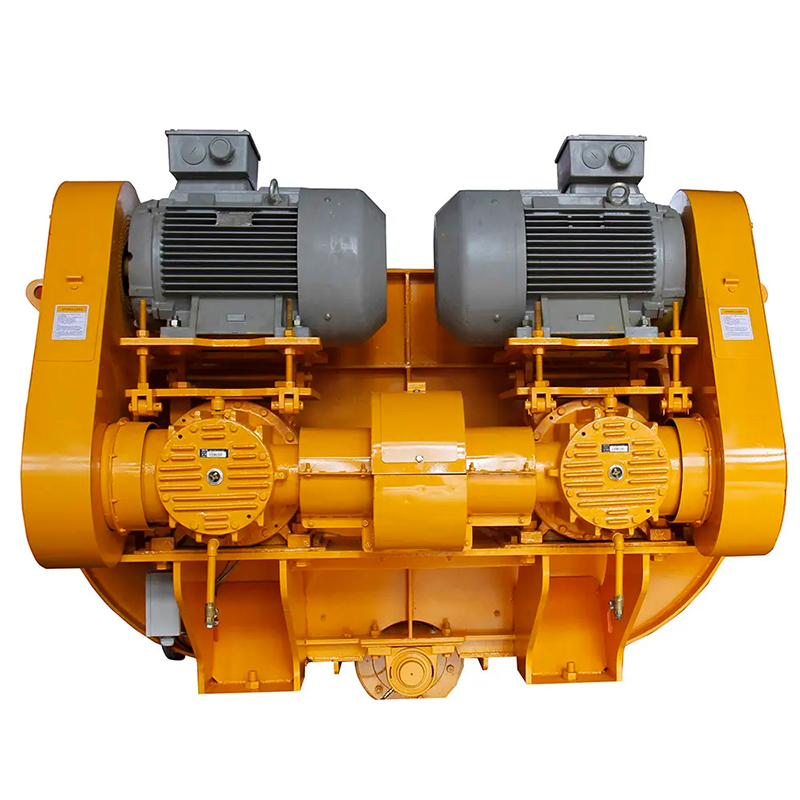

A warshad shub ah oo aan cagaha lahayn, si ka duwan moodooyinka dhaqameed, uma baahna shaqo aasaasi ah oo faahfaahsan. Fikraddaani waxay kor u qaadi kartaa sunnayaasha bilowga hore, gaar ahaan kuwa loo isticmaalo shaqada aasaasiga ah ee xoogga leh. Laakiin waxa ay bixiso ugu horrayn waa dabacsanaanta meelaynta iyo wakhtiga dejinta oo la dhimay. Ku-tiirsanaan la'aantan aasaaska go'an waxay u tarjumeysaa waqti muhiim ah iyo kaydin kharash.

Zibo Jixiang Machinery Co., Ltd., oo ah hormuudka aaggan (wax badan ka eeg shabakadooda), wuxuu qeexayaa in baabi'inta shaqada dhulka aysan kaliya dhimin waqtiga dhismaha laakiin sidoo kale ay yareyso khalkhalgelinta deegaanka. Hawlgallada baaxadda leh, isbeddellada asaasiga ah ee noocan oo kale ah ee habaynta waxay u horseedi karaan kayd isugeyn la taaban karo.

Intaa waxaa dheer, waxaa sidoo kale jira fududaynta dib u dejinta. Marka mashruucyadu si degdeg ah u guuraan ama u dhammaystirmaan, awoodda loogu wareejinayo geedka meel cusub iyada oo aan la dumin oo dib loo dhisin aasaaska ayaa noqon doonta mid qiimo leh. Badanaa, wax-ku-oolnimadani waxay ka miisaan badan tahay beddelka dhaqameed, gaar ahaan deegaannada mashruuca ee kacsan.

Wax ka qabashada Caqabadaha iman kara

Dabcan, ka beddelashada jaangooyooyinka caadiga ah waxay keenaysaa caqabado u gaar ah. Tusaale ahaan, injineeradu waxay inta badan muujiyaan welwelka ku saabsan xasilloonida. La'aanteed aasaas go'an la'aanteed, sidee si isku mid ah u shaqeyn kartaa geedka noocan oo kale ah oo dhan juqraafiyo kala duwan? Waayo-aragnimada goobta, si kastaba ha ahaatee, waxay soo jeedinaysaa hubinta joogtada ah iyo isu-dheellitirka hagaajinta naqshadeynta inay si fiican u daboolaan walaacyadan.

Xakamaynta tayada ayaa sidoo kale laga yaabaa inay u soo baxdo su'aal caadi ah. Aad bay muhiim u tahay in la hubiyo in dabeecadda guuritaanka ee geedka aysan khatar gelin tayada tayada isku darka la taaban karo. Shirkadaha sida Mashiinnada Zibo Jixiang waxay si madax-furasho ah ula tacaaleen caqabadan iyaga oo raacaya nidaamyo tijaabo ah oo sax ah.

Tababarka rakibidda iyo kartida ayaa u soo baxay arrimo muhiim ah, iyadoo warbixino toos ah ay muujinayaan in kooxaha khibradda leh ay muhiim u yihiin habsami u socodka dhirtan. Qalloocyada waxbarashada ayaa jira, iyo haysashada hawl wadeeno khibrad leh waxay ka dhigtaa farqi la taaban karo ee hufnaanta iyo isku halaynta.

Waxtarka dhabta ah ee aduunka

Codsiyada la taaban karo ayaa inta badan muujinaya faa'iidooyinka aragtida. Daraasad xaaladeed oo ku lug leh shirkad dhisme oo dhexdhexaad ah ayaa muujisay sida warshad aan cagaha lahayn ay hoos ugu dhigtay mashruucoodii ugu horreeyay ilaa 15%. Kaydintani ma ahayn mid dhaqaale oo keliya balse waxa ay sidoo kale bixisay faa'iidooyinka mashruuca istiraatijiyadeed iyada oo la xoreynayo xoogga shaqada iyo qalabka hawlaha xiga.

Jawaab celintoodu waxay muujisay habacsanaan hawleed oo ay ugu wacan tahay kala wareejinta agabka oo la hagaajiyay iyo hoos u dhac ku yimid dib u dhacyada cimilada. Dhirta caadiga ah, cimilada xun waxay inta badan joojisaa shaqada aasaasiga ah. Dabeecadda dabacsan ee a warshad shub ah oo aan cagaha lahayn waxay soo bandhigaysaa faa'iido xusid mudan xaaladahan oo kale.

Si kastaba ha ahaatee, iyada oo kuwan kor u qaadaya waxtarka ay yihiin kuwo soo jiidasho leh, shirkaduhu waxay ka feejignaadaan hubinta tayada. Sheekadu waa sahlan tahay: dhaqsaha badan waa inuusan si ka wanaagsan u tanaasulin. Isku dhafka kormeerka tayada adag ayaa fure u ahaa ilaalinta heerarka sare iyadoo lagu riyaaqayo waxtarka cusub ee la helay.

Sahaminta Hal-abuuro Dheeraad ah

Warshadu kuma joogsato kaliya u gudubka moodooyinka cagaha la'aanta ah. Waxay dhalinaysaa hal-abuur ballaadhan oo naqshadaynta dhirta iyo tignoolajiyada hawlgelinta. Is dhexgalka caqliga leh ee dareemayaasha iyo automation-ka ayaa soo muuqda, iyaga oo ballan qaadaya xitaa faa'iidooyin dheeraad ah oo ku saabsan hufnaanta iyo xakamaynta tayada.

Mashiinnada Zibo Jixiang, oo lagu xusay hab-fikirka hore, waxay sii waddaa maalgelinta xalalka tignoolajiyada horseedka u ah. Tan waxaa ku jira ka faa'iidaysiga otomaatiga si loo sii hagaajiyo isku dhafka iyo habka gudbinta, iyaga oo hufnaan ka dhigaya safka hore ee hammigooda shirkadeed.

Horumarka noocan oo kale ah lagama maarmaan ma aha oo kaliya in la ilaaliyo faa'iidada tartanka laakiin sidoo kale wax ka qabashada baahida sii kordheysa ee mashaariicda dhismaha casriga ah. Marka warshaduhu u dhaqaaqaan dhaqammo waara oo dheeraad ah, tignoolajiyada cag la'aanta ayaa laga yaabaa inay qayb muhiim ah ka noqoto kala-guurka.

Gabagabo

Marka dib loo eego, u wareegida dhirta shubka ah ee aan cagaha lahayn waxay u muuqan kartaa khatar marka hore, laakiin faa'iidooyinka waxtarka leh ee la taaban karo iyo dabacsanaanta hawlgalka ee la bixiyo lama soo koobi karo. Sida hal-abuur kasta, qirashada kharibanaha iman kara iyo ka go'naanta hubinta tayada ayaa muhiim ah. Shirkadaha hormuudka ka ah kharashka, sida Mashiinnada Zibo Jixiang, ayaa meelkan ka dhigay tusaale xusid mudan. Kuwa doonaya in ay la qabsadaan, mustaqbalku waxa laga yaabaa in uu ahaado mid waxtar leh oo aan cagaha lahayn.

Marka la soo koobo, waxay ku saabsan tahay isku dheelitirka horumarka iyo dhaqanka, hubinta in tignoolajiyada cusubi aysan kaliya ballanqaadin waxtarka laakiin ay si joogto ah u bixiso. Socdaalka hal-abuurku waa socdaa, qaybta dhismuhuna waxay u taagan tahay inay si weyn uga faa'iidaysato isbeddelladan xiisaha leh.

Waqtiga boostada: 2025-09-22