सामग्री

यो लेख एक विस्तृत सिंहावलोकन प्रदान गर्दछ जापानी प्रविधि कंक्रीट ब्याचिङ प्लान्टहरू, तिनीहरूका सुविधाहरू, फाइदाहरू, अनुप्रयोगहरू, र चयनका लागि विचारहरू कभर गर्दै। तपाइँ तपाइँको ठोस उत्पादन आवश्यकताहरु को लागी सही समाधान छनोट गर्न को लागी हामी बिरुवाहरु को बिभिन्न प्रकारहरु, क्षमता विकल्पहरु, र महत्वपूर्ण कारकहरु को अन्वेषण गर्नेछौं। मा नवीनतम प्रविधि र प्रगति बारे जान्नुहोस् जापानी प्रविधि कंक्रीट ब्याचिङ प्लान्टहरू आफ्नो कार्यहरू अनुकूलन गर्न र दक्षता सुधार गर्न।

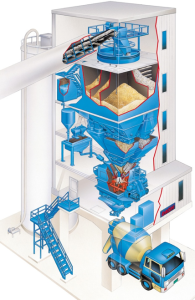

बुझ्दै जापानी प्रविधि कंक्रीट ब्याचिङ प्लान्टहरू

के हुन् जापानी प्रविधि कंक्रीट ब्याचिङ प्लान्टहरू?

जापानी प्रविधि कंक्रीट ब्याचिङ प्लान्टहरू कंक्रीटको सटीक र स्वचालित उत्पादनको लागि डिजाइन गरिएको अत्यधिक कुशल र भरपर्दो प्रणालीहरू हुन्। तिनीहरूले ब्याचिङ प्रक्रियालाई सुव्यवस्थित बनाउँछन्, निरन्तर गुणस्तर सुनिश्चित गर्दै र श्रम लागत घटाउँछन्। यी बिरुवाहरू विभिन्न आकारहरू र कन्फिगरेसनहरूमा आउँछन् जुन विभिन्न परियोजना स्केलहरू पूरा गर्न, साना-स्तरीय निर्माणदेखि ठूला-पूर्वाधार परियोजनाहरूमा। ब्रान्ड नवाचार र टिकाउ निर्माणमा ध्यान केन्द्रित गर्नका लागि परिचित छ।

को प्रकारहरू जापानी प्रविधि कंक्रीट ब्याचिङ प्लान्टहरू

जापानी प्रविधि को दायरा प्रदान गर्दछ जापानी प्रविधि कंक्रीट ब्याचिङ प्लान्टहरू, सहित:

- स्टेसनरी प्लान्टहरू: यी स्थायी स्थापनाहरू ठूला-ठूला, निरन्तर सञ्चालनका लागि आदर्श हुन्। तिनीहरू उच्च क्षमता प्रदान गर्छन् र दीर्घकालीन प्रयोगको लागि डिजाइन गरिएका छन्।

- मोबाइल प्लान्टहरू: यी पोर्टेबल प्लान्टहरूले विभिन्न स्थानहरूमा परियोजनाहरूको लागि लचिलोपन प्रदान गर्दछ। तिनीहरू ढुवानी गर्न र सेट अप गर्न सजिलो छन्, तिनीहरूलाई विभिन्न निर्माण साइटहरूको लागि उपयुक्त बनाउँदै।

- कम्प्याक्ट प्लान्टहरू: साना परियोजनाहरूको लागि डिजाइन गरिएको, यी बिरुवाहरूले क्षमता र पदचिह्न बीच सन्तुलन प्रदान गर्दछ, अन्तरिक्ष-प्रतिबन्धित वातावरणको लागि आदर्श।

को मुख्य विशेषताहरु र लाभहरु जापानी प्रविधि कंक्रीट ब्याचिङ प्लान्टहरू

उन्नत प्रविधि र स्वचालन

धेरै जापानी प्रविधि कंक्रीट ब्याचिङ प्लान्टहरू कम्प्युटर-नियन्त्रित ब्याचिङ र तौल प्रणालीहरू सहित उन्नत स्वचालन प्रणालीहरू समावेश गर्नुहोस्। यसले सटीक सामग्री अनुपात, लगातार कंक्रीट गुणस्तर, र न्यूनतम फोहोर सुनिश्चित गर्दछ। यी प्रणालीहरूले प्राय: सजिलो सञ्चालन र निगरानीको लागि प्रयोगकर्ता-अनुकूल इन्टरफेसहरू समावेश गर्दछ।

उच्च उत्पादन क्षमता र दक्षता

मोडेल र कन्फिगरेसनमा निर्भर गर्दै, निक्को कंक्रीट ब्याचिङ प्लान्टहरू उत्पादन क्षमता को एक विस्तृत श्रृंखला प्रदान। तिनीहरूको कुशल डिजाइनहरूले डाउनटाइमलाई कम गर्छ र आउटपुटलाई अधिकतम बनाउँछ, जसले ठूला परियोजनाहरूमा महत्त्वपूर्ण लागत बचत गर्दछ। सटीक ब्याचिङले न्यूनतम सामग्री फोहोर सुनिश्चित गर्दछ, थप दक्षता बढाउँदै।

टिकाऊ निर्माण र भरपर्दो प्रदर्शन

जापानी प्रविधि कंक्रीट ब्याचिङ प्लान्टहरू चुनौतीपूर्ण वातावरणमा दीर्घायु र भरपर्दो कार्यसम्पादन सुनिश्चित गर्दै उच्च गुणस्तरीय सामग्री र कम्पोनेन्टहरूद्वारा निर्मित। नियमित मर्मतसम्भार र टिकाउ भागहरूको प्रयोगले यी बिरुवाहरूको लामो आयुमा योगदान पुर्याउँछ।

अधिकार छनोट गर्दै जापानी प्रविधि कंक्रीट ब्याचिङ प्लान्ट

विचार गर्न कारकहरू

उपयुक्त छनोट गर्दै जापानी प्रविधि कंक्रीट ब्याचिङ प्लान्ट विभिन्न कारकहरूमा निर्भर गर्दछ, जसमा:

- परियोजना स्केल र आवश्यक ठोस आउटपुट

- उपलब्ध ठाउँ र साइट सर्तहरू

- बजेट र लगानीको प्रतिफल

- विशिष्ट कंक्रीट मिश्रण आवश्यकताहरू

- स्वचालन को स्तर वांछित

क्षमता विचारहरू

क्षमता एक महत्वपूर्ण कारक हो। कंक्रीटको उच्चतम मागलाई विचार गर्नुहोस् र गुणस्तर वा दक्षतामा सम्झौता नगरी ती आवश्यकताहरू पूरा गर्न सक्ने बिरुवा छनोट गर्नुहोस्। क्षमताभन्दा बढी मूल्याङ्कन गर्नाले अनावश्यक खर्च निम्त्याउन सक्छ, जबकि कम आँकलन गर्दा उत्पादनमा अवरोध आउन सक्छ।

केस स्टडी र अनुप्रयोगहरू

उदाहरण परियोजनाहरू

जापानी प्रविधि कंक्रीट ब्याचिङ प्लान्टहरू विश्वव्यापी रूपमा धेरै ठूला-ठूला पूर्वाधार परियोजनाहरूमा सफलतापूर्वक कार्यान्वयन गरिएको छ। यी अग्लो भवनहरू र पुलहरूदेखि सडक र बाँधहरूसम्म छन्। सफल कार्यान्वयनहरू प्रदर्शन गर्ने विस्तृत केस अध्ययनहरू प्राय: निर्माताको वेबसाइट वा उद्योग प्रकाशनहरू मार्फत फेला पार्न सकिन्छ। विशिष्ट उदाहरणहरूको लागि, निक्कोलाई सिधै सम्पर्क गर्नु वा तिनीहरूको आधिकारिक स्रोतहरूसँग परामर्श गर्नु उत्तम हुन्छ।

निष्कर्ष

जापानी प्रविधि कंक्रीट ब्याचिङ प्लान्टहरू कुनै पनि ठोस उत्पादन सञ्चालनको लागि महत्त्वपूर्ण लगानी प्रतिनिधित्व गर्नुहोस्। यद्यपि, लाभहरू - सुधारिएको दक्षता, लगातार गुणस्तर, र कम फोहोर - प्रायः प्रारम्भिक लागतहरू भन्दा बढी हुन्छ। परियोजना स्केल, क्षमता आवश्यकताहरू, र बजेट जस्ता कारकहरूको सावधानीपूर्वक विचार गर्दा तपाईंले आफ्नो विशिष्ट आवश्यकताहरू पूरा गर्न इष्टतम बिरुवा चयन गर्नुहुनेछ। थप जानकारीको लागि, भ्रमण गर्नुहोस् Zibo jixiang मेसिनरी कं, लिमिटेड, उच्च गुणस्तरको कंक्रीट ब्याचिङ उपकरणको एक अग्रणी प्रदायक। यद्यपि तिनीहरूले Nikko ब्रान्डलाई विशेष रूपमा प्रस्ताव नगर्न सक्छन्, तिनीहरूले तपाईंलाई उपयुक्त विकल्पहरूको बारेमा सल्लाह दिन सक्छन् र तपाईंको आवश्यकताहरूको लागि उत्तम समाधान छनोट गर्न विशेषज्ञ मार्गदर्शन प्रदान गर्न सक्छन्।

पोस्ट समय: 2025-08-27