Ka whakaratohia e tenei aratohu he tirohanga whanui mo Nga tipu raima Fabo, e hipoki ana i o raatau ahuatanga, painga, paearu whiriwhiri, me nga whakaaro mo te mahi tino pai. Ka tuhurahia e matou nga momo tipu, ka matapaki i nga mea tino nui ki te whiriwhiri i te punaha tika mo o hiahia, me te whakatika i nga wero noa e pa ana ki a raatau mahi. Akohia me pehea te whakanui ake i te pai me te whai hua me to Te tipu raima Fabo haumi.

Te Maramatanga ki nga Tipu Raima Fabo

He aha nga Tipu Raima Fabo?

Nga tipu raima Fabo tirohia nga punaha hanga raima tomua, he maha nga wa e whakauru ana i nga hangarau matatau mo te whakaranu aunoa, te hanga, me te whakamaarama. Ko enei tipu he rereke te rahi, te kaha, me te taumata o te mahi aunoa, mai i te iti-iti, nga mahi a-ringa ki te tino aunoa, nga taputapu teitei. Ko nga ahuatanga motuhake o a Te tipu raima Fabo ka whakawhirinaki nui ki te kaihanga me nga whakaritenga a te kiritaki. Ko te whiriwhiri i te tipu tika he mea nui mo te whai hua me te whai hua.

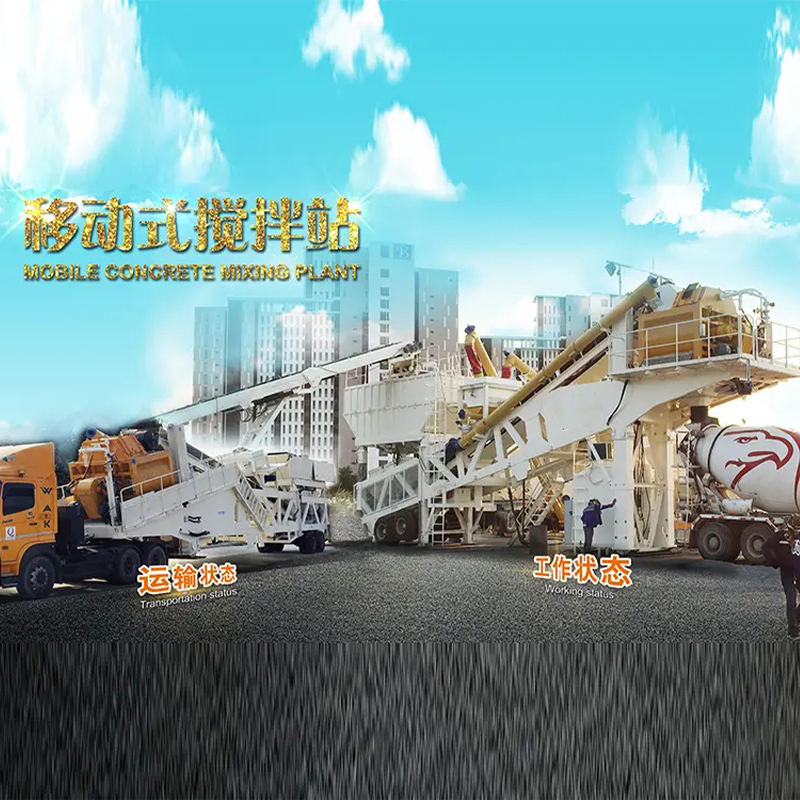

Nga Momo Raima Raima Fabo

He maha nga momo Nga tipu raima Fabo kei te noho, e tika ana mo ia momo whakaputanga me nga waahanga kaupapa. Kei roto pea i enei ko nga tipu pūkoro, nga tipu tuuturu, me nga mea i hangaia mo etahi hua raima (penei i nga poraka, i nga paera, i nga huānga o mua ranei). He maha nga wa ka tukuna e nga Kaihanga etahi otinga whakarite hei whakatutuki i nga hiahia a te kiritaki. Ko te whiringa ka whakawhirinaki ki nga ahuatanga penei i te tahua, te rahinga whakaputa, te waatea o te whenua, me nga momo hua raima hei hanga.

Te Whiriwhiri i te Tipu Raima Tika Fabo

Nga take hei whakaaro ina whiriwhiri ana i te whare raima Fabo

Te whiriwhiri i te pai Te tipu raima Fabo me āta whakaaro ki ngā āhuatanga maha. Ko nga waahanga matua ko:

- Raukaha Whakaputa: Whakatauhia to hua e hiahiatia ana ia ra, ia tau ranei hei kowhiri i tetahi tipu e tika ana te kaha.

- Momo Hua Raima: Ko te hoahoa o te tipu me hono ki nga hua raima motuhake e hiahia ana koe ki te hanga.

- Taumata Aunoa: Whakaarohia te taumata o te aunoatanga e hiahiatia ana, me te whakataurite i te haumi tuatahi me te pai o te whakahaere.

- Pūtea: Whakaritehia he tahua moni e whakaatu ana mo te hoko tuatahi, te whakaurunga, me nga utu whakahaere tonu.

- Nga Whakaritenga Mokowā: Aromatawai i te waahi e waatea ana kia pai ai te noho pai o te tipu ki roto i to whare.

Te whakatairite i nga Tauira Tipu Raima rereke Fabo

Whakataurite tika o rereke Te tipu raima Fabo he mea nui nga tauira. Engari, me te kore e tohu i nga tauira a te kaihanga, kaore e taea te whakataurite taipitopito. Heoi, ko nga mea penei i te tere o te whakaputa, te riterite o te kounga raima, te kaha o te kaha, me nga whakaritenga tiaki me whakataurite ma te whakamahi i nga whakaritenga a nga kaihanga. Me tono i nga wa katoa nga taipitopito hangarau mai i nga kaiwhakarato pea. Ka kitea e koe etahi atu korero mo nga momo tipu raima ma te whakapiri atu ki nga kaihanga taputapu me te toro atu ki nga whakaaturanga ahumahi.

Te whakapai ake i to Tipu Raima Fabo

Te Whakanuia i te Pai me te Hua

Ina oti koe te whakauru i to Te tipu raima Fabo, ko te arotau i tana mahi he mea matua ki te whakanui i nga hokinga mai. He mea nui te tiaki i nga wa katoa, nga kaiwhakahaere mohio, me te pai o te whakahaere rauemi mata mo te whakaputanga kounga teitei. Ma te whakatinana i te punaha whakahaere kounga pakari ka whakarite kia rite nga hua me te whakaiti i te ururua.

Raparongoā Nga take noa

Nga raruraru noa ki Nga tipu raima Fabo kei roto pea i nga mahi kino o nga taputapu, te koretake o te kounga o te ranunga raima, me te hangahanga pounamu. Ko te tiaki me te aukati i nga wa katoa ka tino whakaiti i enei take. I tua atu, ko te rapu tohutohu tohunga mai i te kaihanga, i nga tohunga hangarau mohio ranei ka tohutohuhia ina raru nga raru uaua.

Whakapā Zibo Jixiang Machinery Co., Ltd. mo to Hiahia Tiu Raima

Mo nga otinga tipu raima-kounga teitei me te pono, whakaarohia te tirotiro i nga tuku mai Zibo Jixiang Machinery Co., Ltd.. He maha nga taputapu me nga ratonga hei tautoko i o hiahia hanga raima. Whakapa atu ki a raatau ki te ako atu mo o raatau Te tipu raima Fabo kōwhiringa ranei etahi atu miihini hanga raima.

Whakakahoretanga: Ka whakaratohia e tenei tuhinga nga korero whanui. Nga korero motuhake mo Nga tipu raima Fabo ka rereke i runga i te kaihanga me te tauira. Me toro atu ki nga tuhinga a te kaiwhakanao me nga whakaritenga mo nga korero tika.

Wā tuku: 2025-10-23